WorkSafe BC has approved proposed amendments to Part 26: Forestry Operations to include a subsection for Arborist Activities. There is a four month transition from the Board of Director’s approval of this amendment to when it becomes law on December 1st, 2021. You can review the changes here: https://www.worksafebc.com/en/law-policy/public-hearings-consultations/closed-public-hearings-and-consultations/bod-approves-2020-and-2021-amendments-ohsr-may-2021

Will this have implications for your workplace and more directly your own work practices? Yes. Why are these regulations being adopted? Industry has not effectively addressed the rate of fatal and severe injury incidents to workers in the province, and the high insurance premiums or non-compliance penalties Tree Services pay haven’t deterred dominant behaviours. Through consultations with industry leaders representing different segments of the industry, WorkSafe BC has implemented regulations that will be an adjustment for small and large businesses alike.

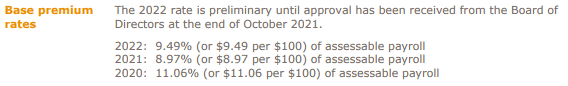

Source: WorkSafe BC Tree Services Classification Unit Description and Rates

Reactions to these regulatory changes were mixed during the consultation period; resistance from some vocal industry participants targeted time and money. Yes, initially these changes will cost time and money. The playing field is about to be legally levelled with a recipe that promises to address our industry’s high rate of incidents. We can anticipate some will opt out of compliance although WorkSafe BC has assured us that Prevention Officers will be provided training ahead of adoption (December 1st, 2021) and that Tree Services will be a focal point for site inspections.

Key themes of the new Arborist Activities amendment to Part 26 of WorkSafe BC’s Occupational Health and Safety Regulation include definitions, arborist activities planning, tree climbing equipment, tree climbing planning, and tree climbing procedures. The entire part has been framed as a non-prescriptive, best practices approach which will require some legwork for workplaces to demonstrate compliance and due diligence. For the many Arborists working in BC having been trained outside of the province or out of the country, this new regulation could improve working conditions as credentials, training, education and experience from outside of the province becomes recognized. For example, OHSR Part 26.1: Definitions describes the following:

“qualified arborist”

means a person who

(c) has, as appropriate to the work being done, knowledge, through training or a combination of education and training, of and experience

Note that there is no measurement of experience, knowledge or training, or examples given of what education might be “appropriate to the work being done”. To paraphrase, Qualified Arborist means a person who has demonstrated beyond a reasonable doubt to a panel of occupational health and safety peers (including industry subject matter experts) that the person is competent to perform the task they have been assigned to complete. This is not simply tree climbing, but most scenarios a tree climber is likely to encounter. Third party industry trainers and credentialing organizations have an important role in supporting workers to demonstrate compliance with this definition of Qualified, although internal workplace training may suffice so long as the trainer is Qualified and the training provided meets industry standards/best practices.

Flexibility enabled through this non-prescriptive approach can lead to confusion and frustration, and this is where collaboration with your regional tree care community partners can be quite helpful. One source of confusion and handwringing through the consultation phase of this amendment was related to Part 26.12.0.3 which provides context for inspections of trees and creation of a tree climbing plan, and the requirement for the documenting of that plan. Imaginations ran wild on this section, with suggestions that this added time tax burden would drive owners out of business. While there will undoubtedly be some time cost associated with completion of a site level hazard assessment, our industry’s safety performance continues to lag behind other industries that have taken strides to measurably reduce rates of incidents. A document alone offers no physical protection from harm, but the process of crew participation in a site level hazard assessment has time and again proven its value in reducing incidents, in preparing workers to respond quickly and effectively in emergencies, and to support an improved workplace safety culture.

Tree workers transitioning into compliance with this new regulation can take a few important steps to help make this process relatively painless so we can get to the benefits sooner (fewer workers being hurt or killed on the job):

Let your employer know about these regulatory changes and offer your support in reaching compliance. Although efforts have been made to spread the word about this new regulation, many workplaces will have no idea of its existence. Employers do have a legal obligation to comply with the regulation although early adoption will only be possible if the employer is made aware of the new regulation and the workplace works together to implement required changes.

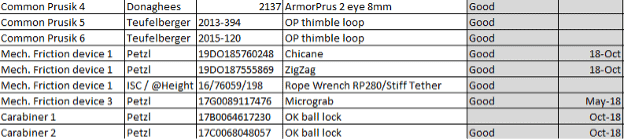

Create a PPE inspection spreadsheet. Documenting your fall protection and rigging equipment is one simple task that can address multiple requirements under Part 26.12.06 Tree-climbing equipment. The ISA ITCC has produced a PDF inspection formwith a simple layout that could be recreated unique to your workplace. From here on out, future gear purchases should be fit for the purpose of industrial tree climbing and certified/labeled with traceable product information. There must be technical information for the product that addresses inspection and retirement criteria, configuration, operating limits and load ratings, and these should be available to the gear owner in hard copy or digital format.

Make time with your crew to talk about the hazards, and document them before you start working. These are hazards specific to your work location and the tree(s) directly or indirectly involved in your work. For every hazard, identify controls you will put in place that will allow the entire crew to work safely around those hazards. Discuss the loads anticipated of required tree work on climbing and rigging anchors and plan systems to minimize the potential for overloading the structure or equipment. Finally, plan for emergencies unique to the conditions you are working in to enable a quick and effective response. All of this can be quickly captured on a tailgate, tailboard, site level hazard assessment, jobsite safety assessment, etc. You can ask nicely for a copy of a tailgate from one of your industry partners and modify it for your own workplace.

Strive for credentials or qualifications. Within the province of BC there is lots to choose from to validate your knowledge, skills, training and experience through qualifications and credentials. Qualifications that set a high benchmark through prerequisites and written/performance skills exams are valuable, as are credentials that set continuing education renewal requirements. Here are some examples:

ITA BC Arborist Technician Certificate of Qualification

ITA BC Climbing Arborist Certificate of Qualification

ISA Certified Treeworker Climber Specialist

ISA Certified Arborist

ISA Tree Risk Assessment Qualification

TCIA Certified Treecare Safety Professional

Keep your resume up to date. Any previous training you’ve received from beyond your workplace should be noted down to demonstrate your commitment to professional development. This can include webinars, conferences, workshops, courses and climbing competitions. Previous work experience is also valuable here, along with your roles and estimated hours performing common tasks. Restricted trades require a Qualified supervisor to sign off on an apprentice’s hours for specific tasks if the apprentice wishes to one day reach qualification. Our trade is not restricted at this time, but we can definitely do a better job of tracking our hours on rope, rigging, on a saw, or in a bucket truck as a starting point.

Check to see if your work practices meet the standard. Safe work procedures should be documented and immediately available to workers in the field. These can be developed in house, and should reflect objective criteria (such as ANSI Z133 for Arboricultural Operations) wherever possible. If your methods of approaching common tasks are not recognized by your industry partners or have been determined to be unacceptable for safety reasons, be prepared to defend your rationale if you want to continue using this method.

Thinking of this regulation as more of a carrot and less of a stick is to everyone’s benefit. As workplaces transition to reach this new standard set, fewer lost time injury incidents, fewer fatal incidents, and reduced insurance premiums will result. A little further down the road we might find reduced stigma associated with dangers of the tree care profession, longer careers and better quality of life for Arborists, and improved outcomes in recruiting new workers.

Have specific questions about the new Arborist Activities regulations? Let’s hear them.

Two is better than one

Two is better than one SRT – What is all the fuss about?

SRT – What is all the fuss about? There’s no need to scream & shout!

There’s no need to scream & shout!